INNOVATION FUND

Driving clean innovative technologies towards the market

HYVALUE: Novel upcycling production process, based on an innovative circular business model, for high-quality hydrogen production through urban waste streams valorisation

Project summary

Project summary

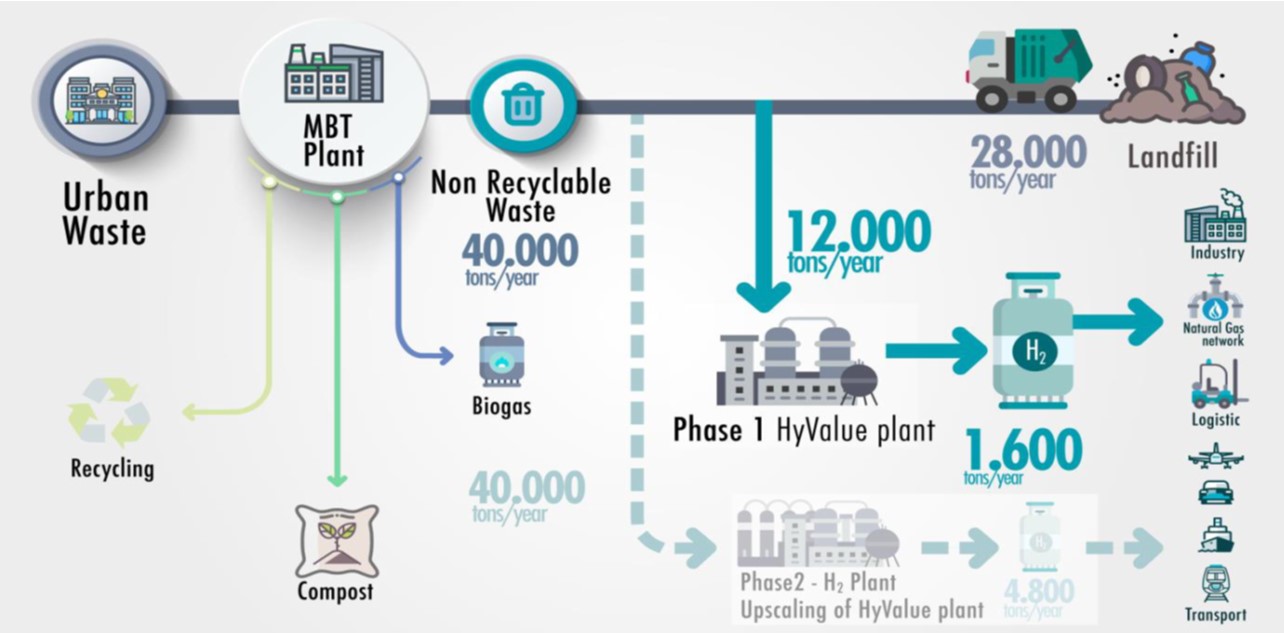

The HYVALUE project will produce high quality hydrogen based on an innovative production process using, amongst other, municipal solid waste. The project, designed and executed by Novargi, will annually produce 1 600 tonnes of hydrogen for mobility and industrial sectors, using 12 000 tonnes of refuse municipal solid waste

High hydrogen production yields with a more energy efficient process

The demonstration facility of the HYVALUE project, based on the technology developed by Novargi and IET Ecology, will produce high-quality hydrogen (>99.9% purity) in the municipality of Vitoria-Gasteiz (Spain), using as feedstock local Municipal Solid Waste (MSW) otherwise destined to landfill. Aside from the MSW, which includes refuse-derived fuels (RDF), plastic wastes and biomass, other common urban residues such as wastewater treatment plant sludge or automobile defragmentation wastes could be processed using this technology.

The project introduces an innovative design and a combination of state-of-the-art gasification technologies that increase the hydrogen yield. Specifically, the system is designed to prioritize low energy and low temperature processes to the maximum extent, which translates into high hydrogen production yields in a more energy efficient process.

Circularity: using landfill waste to decarbonise energy intensive industries

The high purity hydrogen produced in the installation will be suitable for mobility and industrial applications with the ambition to help decarbonise those sectors. Based on a hydrogen production capacity of 1 600 tonnes per annum (tpa), the project will avoid more than 130 000 tCO2e net absolute emissions during its first ten years of operation. This project will also prevent the landfilling of 10 200 tonnes per year of waste, corresponding to an 85% reduction of the processed raw materials, thus, also reducing the risks associated with fire, health, leachates, land and localised air pollution in landfills.

This technology is in line with the circular economy principles and provides economic and societal benefits at the same time. Local industries (the metal sector especially) will benefit from the increase in a local supply of clean hydrogen that will contribute to their low carbon transition, create new green jobs, and boost hydrogen-related R&D investment.

Scale-up potential within the waste management value chain anywhere in Europe

This technology can be easily replicated in other sites within the waste management value chain anywhere in Europe. Such a market development will be encouraged by the EU requirement to reduce the landfilled municipal waste to 10% by 2035 (in Spain, the rate is currently in the 50% range). In this context, the technology replication is already underway, with an up-scaled installation projected for the Vitoria-Gasteiz municipality (Spain) to treat 100% of the waste currently destined to landfill. Additionally, cost competitive hydrogen availability will help local institutions in promoting hydrogen use in high value-added applications, such as energy intensive industries, logistics and mobility.